_thumbnail.jpg)

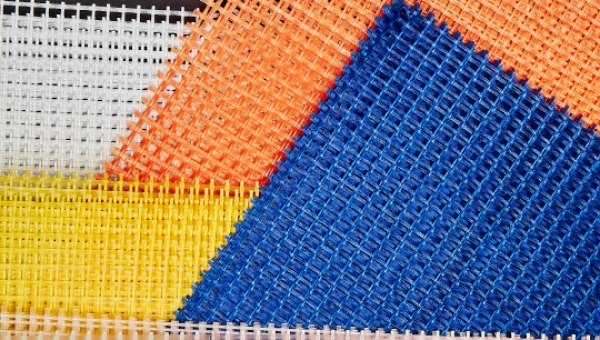

What you should pay attention to when choosing a glass mesh.

Breaking load

This parameter determines how large the load is, exceeding which will lead to the rupture of the glass mesh. It is usually indicated in N/5cm. The higher this indicator, the stronger the facade grid.

|

Cell Size

Most manufacturers make their own grid with a 5x5mm cell. This has already become the standard.

Alkali resistance

Any facade glass mesh must be alkali-resistant, because being in a layer of plaster, it is constantly in a weak alkali-resistant environment. And if the manufacturer did not make an alkali-resistant mesh, then literally within a year it will dissolve and there will be no trace of it. The facade will begin to crack and this promises investments in the restoration of the facade.

How to check the alkali resistance of the facade glass mesh?

In order to check whether the facade glass mesh is really alkali-resistant, you can place a small piece of the facade mesh in a container with a soap solution. As you know, a soap solution is a weak alkaline solution. After 2-3 days, if the mesh has not lost its characteristics, then it is an alkali-resistant facade glass mesh.

Density (weight 1 m2)

The density of the façade glass mesh is a parameter indicating how much 1 m2 of the façade glass mesh weighs. Unscrupulous manufacturers, as a rule, overestimate this parameter, but it is not so difficult to check. For example, you are planning to purchase a façade glass mesh with a density of 160 g/m2. The manufacturer indicated that the roll is 50m2. Thus 50m2 x 160 gr/m2 = 8kg. And if the roll weighs less, then either the density is too high or the roll is less than 50 m2.

Honesty of winding

There are the most “enterprising” manufacturers, in whose rolls, instead of the declared 50 meters, there were 30-35 meters of linear ones. Therefore, when buying a grid, do not take risks and do not overpay, but check! And choose Mahina-TST construction grids, a manufacturer that vouches for its products!

EN

EN  RU

RU